Product Catalog

Contact Us at 970-232-9344

To discuss your product needs!

Voyager Instruments is a Distributor of NI Products.

For more than 40 years, NI has developed automated test and automated measurement systems that help engineers solve the world's toughest challenges.

Contact us a for a quote and to discuss your product needs.

InsightCM for Condition Monitoring

Open Condition Monitoring Software for Maintenance Professionals

NI InsightCM™ is online asset-monitoring software for subject matter experts and maintenance professionals who need:

- Full access to waveform data

- Multiple sensor technology inputs

- Connectivity to existing enterprise software packages

- A variety of configuration options for alarms and data management

NI InsightCM connects to a family of NI monitoring devices to monitor asset health sensor data from any critical equipment in your plant.

Fig 1. Web-based trending and analysis tools help machine analysis diagnose problems from anywhere with network access. (Standard vibration analysis viewer shown in image)

Fig 2. The typical InsightCM system architecture connects wired and wireless sensors from multiple plant assets to IT networks, enterprise digital technology, and subject matter experts.

InsightCM Benefits

Improve Productivity with Remote Diagnostics

InsightCM helps analysts and plan personnel shift focus away from manual data collection, freeing up time for more value-add activities such as data analysis, maintenance planning, and plant operations. Included features let you:

- Log in to the InsightCM server from any web browser with network access and perform real time analysis

- Cover more assets across your fleet with your existing team

- Get to analysis faster with data screening, alarming, and multi-sensor analysis tools

NI Monitoring Devices for Any Asset

NI CompactRIO

NI Continuous Monitoring Systems connect directly to existing protection systems through the buffered analog outputs. This pass-through approach lets maintenance teams add modern, connected, online monitoring systems to legacy hardware with limited communication and analysis capability. Additionally, the buffered analog outputs serve as the security firewall to let plants connect data to standard, business IT networks, without a data diode, rather than the highly protected control networks.

NI Continuous Monitoring Systems connect to existing protection systems through the buffered analog outputs to add modern online monitoring analysis to legacy, or secured, protection systems.

Continuous Monitoring System Key Features

Continuous Monitoring Systems are built on a rugged measurement system (NI CompactRIO) and feature four or eight slots for sensor-specific modules. High-speed voltage input modules are used for connection to the output from the buffered analog output on the protection rack.

Note: Module configurations for Continuous Monitoring Systems are specific to the asset and InsightCM toolkits. Please contact your Voyager Instruments representative for configuration assistance.

FIG 5.

Continuous Monitoring Systems (eight-slot option shown) are built on NI CompactRIO systems; proven technology with more than 15 years of deployment in a variety of heavy industries.

Hardware Specifications

- Dual 10/100/1000 ENET Ports

- Up to Quad-Core Intel Atom Processor

- Passively cooled, -40 °C to 70 °C

- SSD for Temporary Local Storage

- NI InsightCM Monitoring System Firmware

- NI Linux Real-Time OS

Intelligent Data Triggering with Continuous Monitoring Systems

Continuous Monitoring Systems intelligently capture data based on a configuration you specify, which reduces overall data volume and provides a way to isolate important asset events. Use the following events to trigger a data capture:

- Time—Data is captured in user-configurable time intervals such as once an hour, once a day, three times a day, and so on. Choose when to capture the features calculated (less data), the full waveform (more data), or both.

- Change in engineering units (delta EU)—Data is captured when a calculated feature changes by the set delta value with respect to the initial measured value. Once the trigger condition is met, the trigger resets from the latest value but retains the same delta limit. This feature is most often used for ramp-ups and coast-downs, during which data recordings at periodic rotational speeds are desired; for example, recording a 4 s waveform every 50 rpm during ramp-up.

- Alarm limits—Data is captured when a measured feature crosses a preset limit. You must acknowledge alarms before re-triggering.

- Force trigger—You can request a real-time reading using the force trigger option in the action menu for any device. This feature is good for troubleshooting sensor connections, spot-checking an asset, or investigating the current state before acknowledging an alarm.

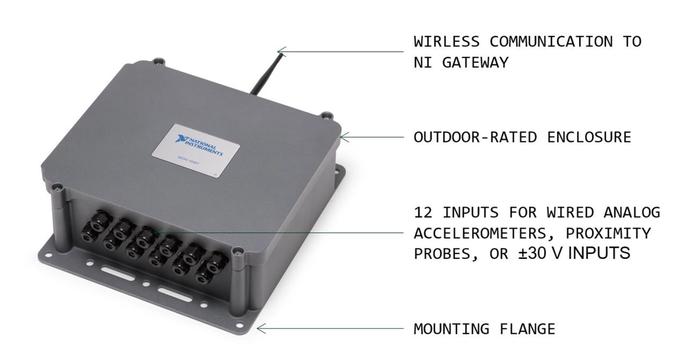

Wireless Vibration Measurement Devices

Wireless Vibration Measurement Devices connect to standard asset-mounted analog sensors and use wireless communication to send diagnostic-quality waveform data to an InsightCM server. Install the system near the monitored asset with the built-in mounting flange. The rugged enclosure is outdoor-rated for industrial environments and can handle wide temperature ranges as well as washdowns. The wireless monitoring devices have 12 analog input channels that support Insight FDS Sensors, accelerometers, proximity probes, tachometers, and voltage or temperature sensors. All devices ship ready to install and connect to power (either line-powered or battery-powered) and sensors. Once you have installed and commissioned its hardware, the Wireless Monitoring Device transmits data back approximately once a day (user-configurable) via a wireless gateway to the InsightCM server installed on premises or in a virtual machine in your choice of cloud provider. The device also can be manually triggered to send data back to the server.

FIG 16.

Wireless Vibration Measurement Devices acquire full waveforms and transmit the data to InsightCM via a wireless gateway.

Sensor Support

The Wireless Vibration Measurement Device supports the Insight FDS as well and many other sensor types out of the box:

- Insight FDS Sensors

- Accelerometers (IEPE)

- Proximity probes (user-provided)

- Tachometers

- Voltage (±30 V)

- Temperature

Wireless Vibration Measurement

NI MON-1046

12-Channel, 10k FMAX, wireless measurement device for wired accelerometers, tachometers, and dynamic analog sensors (Requires NI Gateway)

Wireless Monitoring Gateway

NI MON-1049

This serves as an interface between up to 25 wireless monitoring devices and Insight.